???????:?????????????????

??? ??? ??? ?? ??? ???

GUO Xiao-lei;TIAN Xin-chun;YE Hao-ran;BAO Xu;QIU Xue-hai;WANG Jin-xin(College of Materials Science and Engineering,Nanjing Forestry University,Nanjing 210037,Jiangsu,China;Leitz (China) Tooling System Co.,Ltd.,Nanjing 211100,Jiangsu,China)

?????[1]???????????????,????210037 [2]??(??)????????,????211100

??????????????2019??3?202-206,?5?

Journal of Northwest Forestry University

?????????????(31500480);????????????????

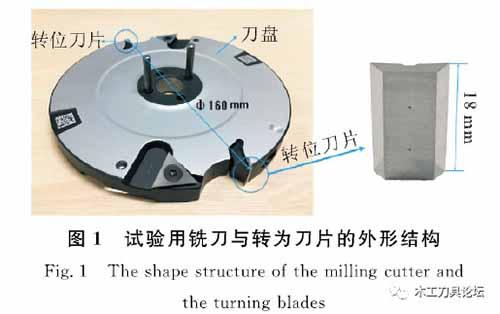

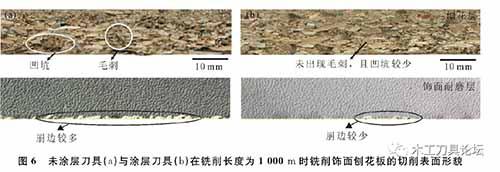

????????????????????????,??????????????????????????CNC????????????????????????????,?????????????????????????,??????????????????????????????,????????????????????????,???????????,???????????????????????????????????????,????????????,??????????????,??????????????;????????????,?????????????????????,???????;???????????,??????????????????????????????????????????????,????????????????????????,?????????????,??????????????????????,??????????????

The milling performance of the cutting tools with fluorinated surfactants-based coatings against decorative particleboard was analyzed to provide theoretical guidance for the application of fluorinated surfactants-based coatings in wood cutting processing.The CNC machining center was used for the milling test of decorative particleboard with uncoated tools and fluorine coated tools.The wear morphology of the tool face was measured and analyzed by tool microscope and scanning electron microscope.The roughness of the machined surface of decorative particleboards was measured by a super depth of field three-dimensional microscope.The cutting performance of the fluorine coated tool during decorative particleboards was studied.It was showed that under the same milling length,the flank wear band width of the fluorine coated tool during the milling of decorative particleboard was significantly lower than the uncoated tool.As the milling length increased,the uncoated tool wear band width increased sharply,while the coated tool wear band width increased slowly.The wear mechanism of fluorine-coated tools was mainly abrasive wear,which could effectively reduce the abrasive wear caused by the adhesive and the particle,and reduce the chipping of cutting edge.Under the same milling length,the cutting surface roughness of the fluorine coated tool during the milling of decorative particleboards was significantly lower than the uncoated tool.The burrs and pits of wood-particles layer and the chipping of wear-resistant layer decreased during the milling of decorative particleboards with fluorine-coated tools.Thus,fluorine coated tool could effectively reduce tool wear and improve the cutting quality during the milling of decorative particleboards.

2、本网转载并注明其他来源的稿件,目的在于传递更多信息,并不代表本网赞同其观点和对其真实性负责。其他媒体、网站或个人从本网转载使用的,请注明原文来源。如若产生纠纷,本网不承担其法律责任。

3、如本网转载稿件涉及版权等问题,请作者及时与我们联系解决,联系方式:18611402939李经理。

- ?????????? 2021-11-28

- ??????? 2021-10-31

- ????????? 2021-09-17

- ????????????? 2021-08-13

- ?????????? 2021-07-02

- ?????? 2021-06-15

- ?????????? 2021-05-20

- ?????????? 2021-05-13

- ???????? 2021-03-24

- ?????3D??????? 2021-03-19